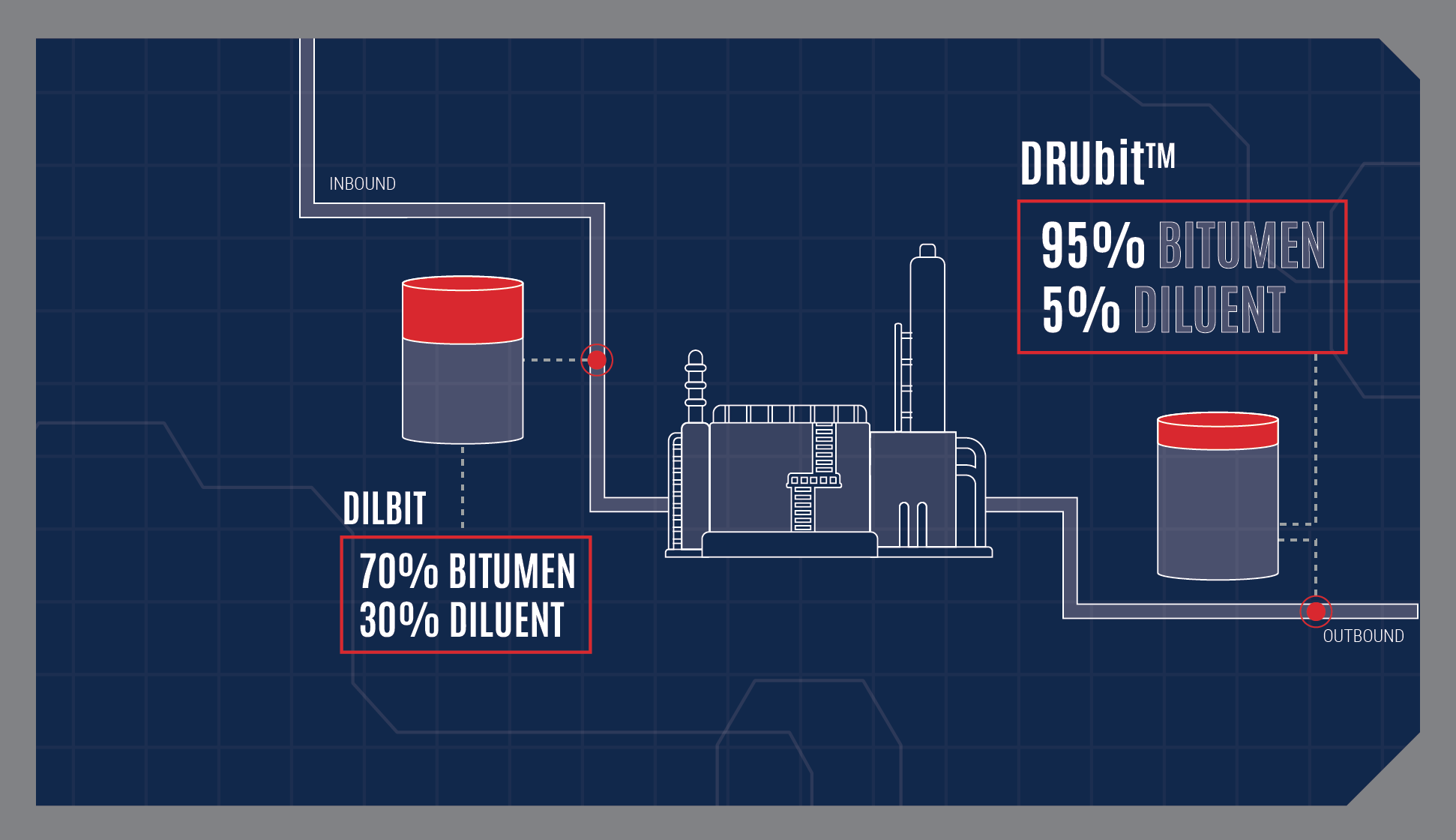

The Diluent Recovery Unit (DRU) located in Hardisty, Alberta Canada is the latest example of how our legacy of pioneering leads to dramatic change for the industry and our partners. By enabling us to deliver DRUbitTM, which contains 95% pure bitumen, and recycle the diluent, we can deliver on a promise of greater safety, sustainability, and enhanced value to our customers.

Patented by USDG, DRUbitTM is a non-hazardous, non-flammable commodity that supports a safer and economically advantaged direct transportation to refineries. By extracting the light diluent component from dilbit (70% bitumen) that is added to facilitate pipeline transportation, the DRU creates a DRUbitTM product that is heavier with increased bitumen concentration (95% bitumen) that can be shipped by rail through the use of coiled and insulated railcars.

Dilbit flows to Hardisty, where the diluent is removed and recycled to the production site for re-use. The refiner customer receives a product that is 95% pure bitumen.

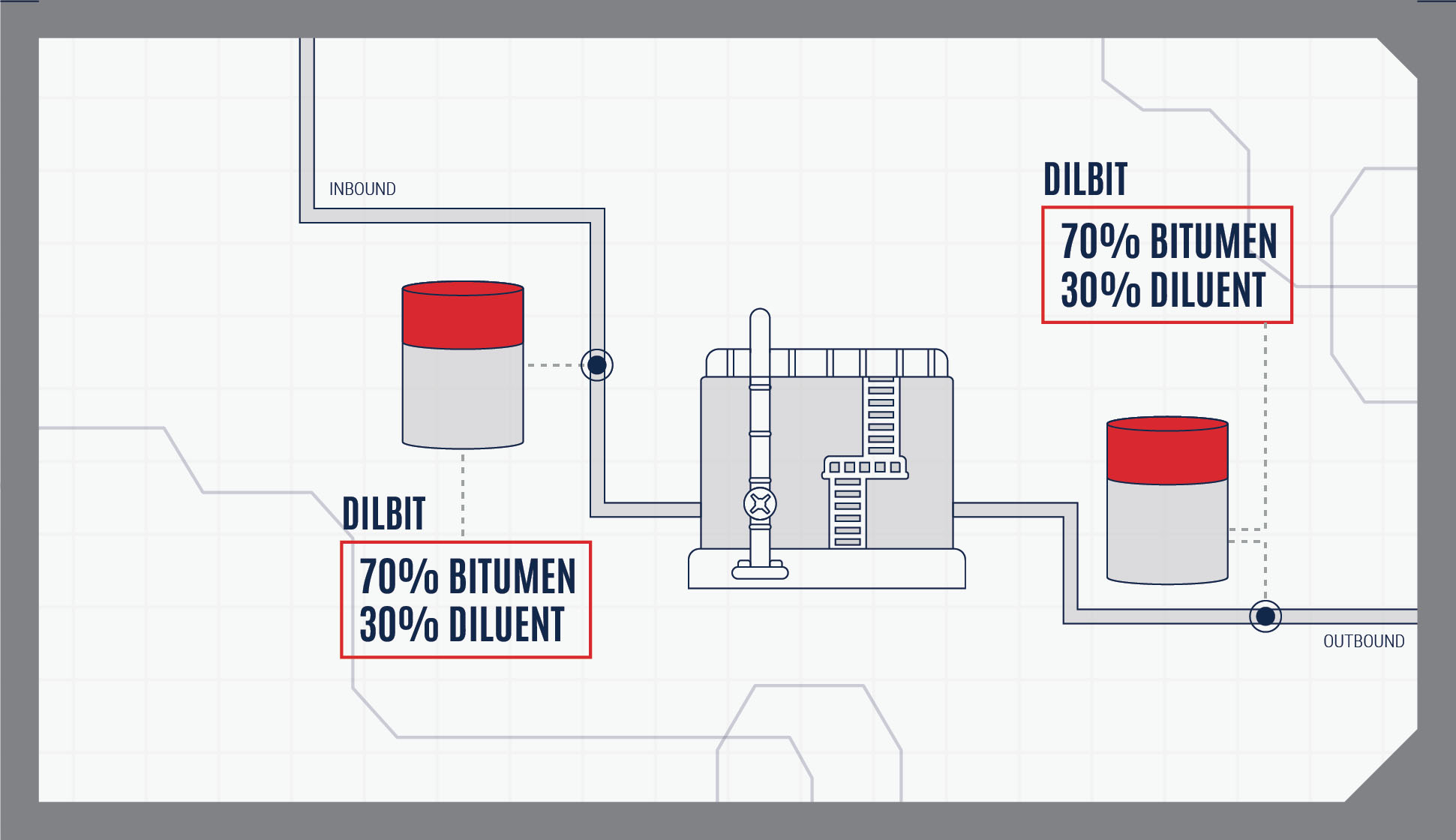

Dilbit flows to Hardistry and then heads to the refinery. The product that arrives has a ratio of 70% bitumen to 30% diluent.

FROM AN INNOVATION, SUSTAINABILITY, AND SAFETY PERSPECTIVE, THIS IS A GAME CHANGER.

THIS IS A VALUABLE PRODUCT WHICH EFFECTIVELY HAS A NEARLY LIMITLESS DEMAND FOR USE THE OIL SANDS.

THE DRU PROCESS IS AN INNOVATIVE SOLUTION THAT HELPS ADDRESS A CRITICAL CHALLENGE TO CANADAʼS OIL PRODUCERS – CONSTRAINED MARKET ACCESS – TO THE BENEFIT OF ALL CANADIANS.

VERY SIMPLY, WE BELIEVE THE PROJECT BENEFITS WESTERN CANADAʼS ENERGY ECOSYSTEM IN A NUMBER OF WAYS, INCLUDING REDUCING CONDENSATE, LOWERING RAIL COSTS, AND VALIDATING ANOTHER FLEXIBLE MARKET OUTLET.